If you’re an inventor who wants to test out your product with a prototype, you might wonder about the best process to accurately create a model to the correct specifications so that you can better understand and show your potential product. You might have concerns about the cost or the length of time that it will take to create a prototype, but there are some great advantages to 3D printing, and you’ll find many solutions to common problems that small-scale inventors and large businesses face when trying to find a way to prototype their new products. There are many risks involved in creating a new product, testing it, and moving it through the supply chain, but 3D printing can alleviate many of the risks.

Risks of the Prototyping Process

When you’re an inventor, there are a lot of risks in not prototyping your product. For instance, you won’t have something tangible to show potential investors, and it will be harder to find potential flaws in your current design. But there are also challenges in prototyping. For instance, you might find it difficult to find a way of testing out your product with multiple materials. But prototyping helps troubleshoot a lot of the potential glitches in your supply chain. When you start with a solid product, which starts with a prototype, you’ll have a greater ability to figure out which types of materials and processes you’ll need to create your product on a mass scale, which will make the rest of your supply chain run more smoothly.

Why 3D Printing is More Effective

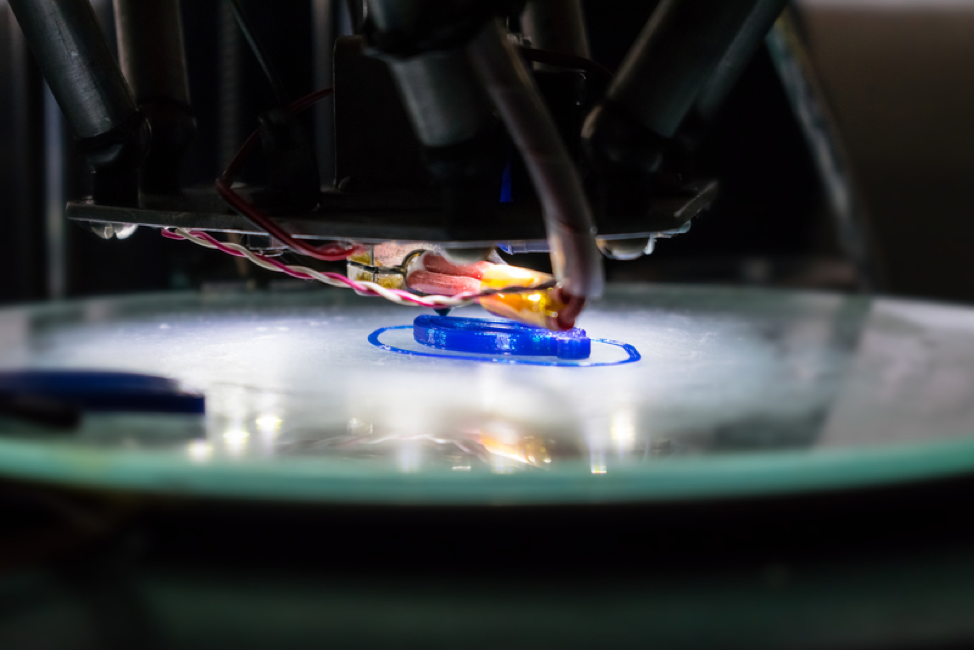

There are a lot of things to know about 3D printing. For instance, large companies have been using it for years to create prototypes for many of their products. Also, the price of 3D printing has come down significantly, so it’s much more feasible for owners of smaller businesses to use this tool. And if you’re concerned about time, this process can actually be an efficient way of testing out your product with multiple materials because they can print in many materials, such as nylon and PETG thermoplastic. Just upload the specifications to the printer once. Then, you can try out your prototype with several materials.

What You’ll Learn by Using 3D Printing for Prototypes

When you create a prototype with 3D printing, you’ll be able to find the glitches with your product, but you’ll also be able to determine other process and funding problems. It can even help you further identify the place it holds to consumers in the market.

Inventing a product is a long process that doesn’t end when you have the proper schematics on paper or disc. To truly know the details about your product and the processes, you’ll need to use to get the product into consumers’ hands, you’ll need a prototype, and 3D printing can be the solution to many problems.

If you are an inventor and you want to start your own business to sell your products, you might run into a few challenges. Check out this other article on the biggest challenges of starting a small business!